4.5.2. Operations with magnetic brake¶

There is an output pin on BPC connector for magnetic brake control, which is installed on the stepper motor shaft. Magnetic brake is used hold motor position in unpowered state.

4.5.2.1. Description of operation¶

Magnetic brake consists of a magnet and a spring, which performs stops the motor shaft. In case there is no voltage applied to the magnet the spring clamps the shaft in place which allows to keep motor position. When voltage is applied the spring releases the shaft.

4.5.2.1.1. Controller operating sequence during stage shutdown.¶

Engine shutdown (the time of shutdown is recorded in controller) -> magnet power supply cut off, shaft fixation -> board power supply cut off

During power-on the sequence is reversed.

Since any movement has inertia, the following parameters are set to control magnetic brake and the position fixation process:

- Time between motor power-on and brake deactivation (ms)

- Time between brake deactivation and readiness for movement (ms)

- Time between engine stop and brake activation (ms)

- Time between brake activation and power-off (ms)

If magnetic brake function is turned off then controller will constantly transmit brake release signal. This allows to move engine equipped with magnetic brake without rotor fixation during pauses. If winding poweroff function is turned off then controller will only pause between brake switching and movement start/stop.

All magnetic brake settings can be changed online and brake will be switched to the mode which would be active in case if the setting would have a new value. For example a large increase of brake activation delay when the brake is already active will lead to brake deactivation and countdown to the new delay value. It is also possible to turn on or off magnetic brake itself or winding power function.

| Type | TTL |

| Active condition ( brake is released) | 0.3 V |

| Passive condition (brake is not powered) | 0 V |

| Operational current | no more than 4 mA |

Magnetic brake setting in XIlab program is described in Brake settings section.

4.5.2.2. Magnetic brake connection diagram¶

For operation with the magnetic brake a special board controlled by digital signal is used. One-axis and two-axis systems, which equipped with this board and able to work properly with magnetic brake are available separately (look below).

4.5.2.2.1. Controller board¶

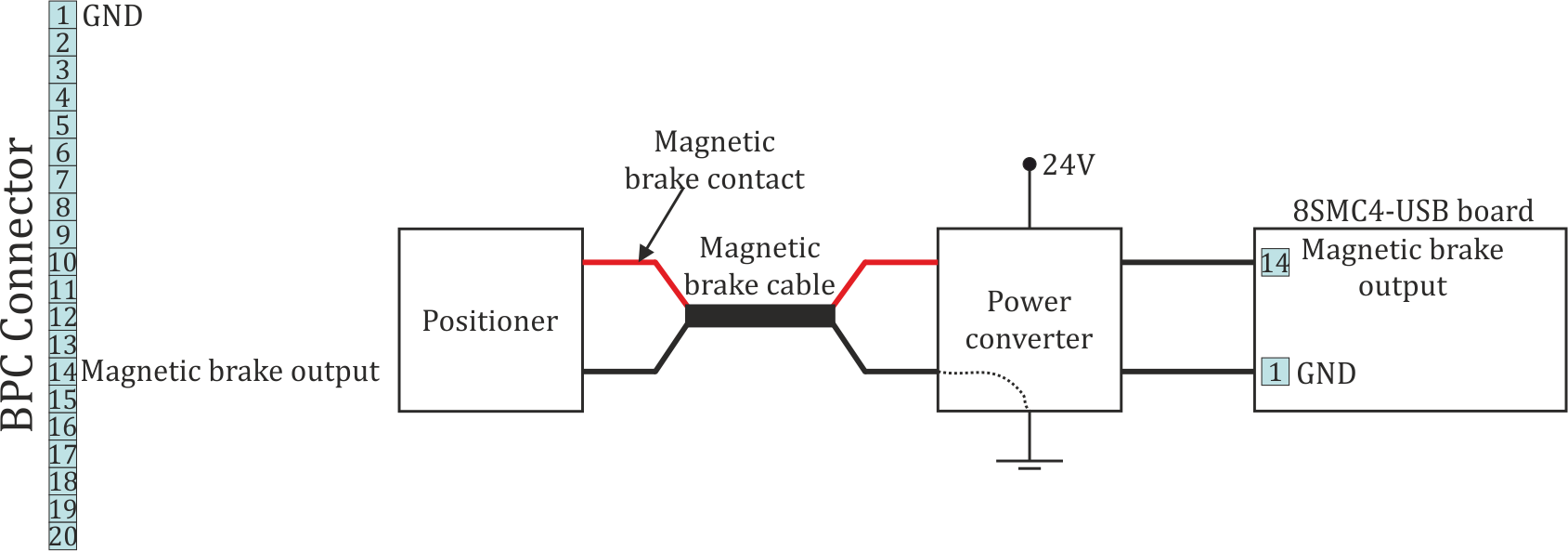

A contact for the magnetic brake control is located on the BPC connector.

Power converter is a converter from digital signals to power. If magnetic brake output is high, the magnetic brake of stage has 24V on its power input. If it is low, the magnetic brake has 0V on its power input. In the most common case a scheme with transistor and diode is used. For more detailed information please contact us: 8SMC4@standa.lt.

4.5.2.2.2. One-axis and two-axis systems¶

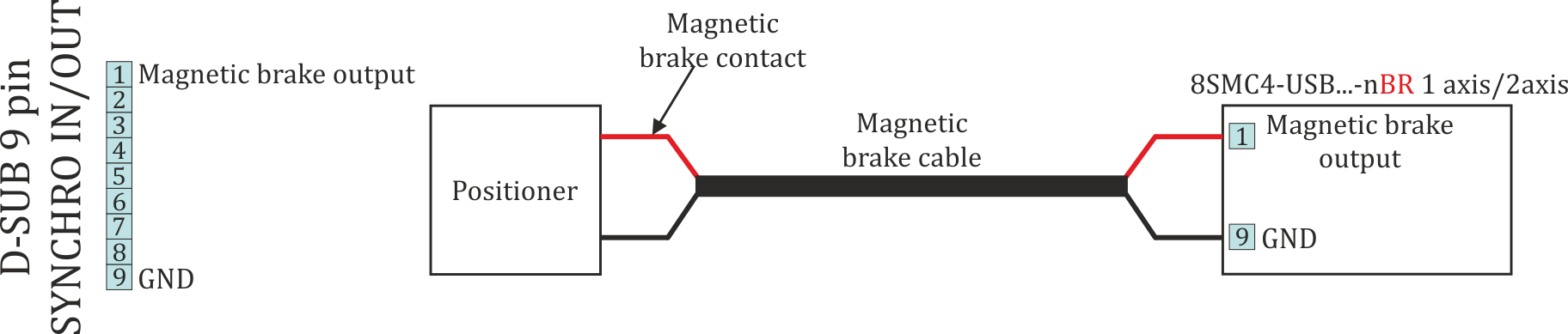

In order to use magnetic brake check if your controller system is equipped with a special converter board. Models which meets this demands can be identified by letters BR in its title, for example 8SMC4-USB-B8-1BR.

Contact pin responsible for magnetic brake control in boxed versions of controller is located on the D-SUB 9 pin connector. A connection diagram is shown below. Two-axis systems are supplied with only one axis which compatible with magnetic brake.

4.5.2.2.3. Multi-axis system¶

In the multi-axis system magnetic brake is not used.