4.3.3. Limit switches¶

4.3.3.1. Limit switches designation¶

Limit switches are designed in order either to prevent the stage movement out of permissible physical movement range or to limit its movement range according to user-defined requirements. Incorrect setting of the limit switches may result to stage jam if the controller goes beyond the permissible range.

Differences between mechanical and optical limit switches.

This video clearly shows how mechanical and optical switches affect the accuracy of homing and

how the position “floats away” as the homing repeats in the xilab software.

4.3.3.2. General settings¶

If the limit switch is active, a corresponding flag is placed in the state structure and the appropriate icon (left or right) is displayed in XILab Main window. The controller can either stop any movement in the direction of any active limit switch (left or right) or stop the movement to the single limit witch (left or right) or not to limit the movement. Limit switches settings are performed in XILab software (see the Motion range and limit switches section).

4.3.3.3. Programmable motion range limitation¶

If there are no hardware limit switches for the motion range but the stage requires such limitation, the programmable limiters can be used. For doing that, the limiters should be switched to limitation mode according to position reading (see the Motion range and limit switches section).

Warning

The programmable motion range limitation is reliable only if there is no direct setting of the new position by ZERO or SPOS commands, or if there is no steps loss or encoder malfunction if it is used for positioning, or if there is no frequent power-cut during the rotation. If any of these problems appears, the programmable range should be re-adjusted. The appropriate reference sensor allows the automatic re-adjustment using the automatic Home position calibration feature.

4.3.3.4. Hardware limit switches¶

The controller may operate with limit switches based either on dry contacts, or on optocouplers, or on reed switches, or on any other sensor types generating a 5 V TTL-standard “logic one” electric signal in one state and a “logic zero” in the other. Each limit witch may be configured independently. There is also possible to change the position of limit switches or their polarity in software.

Note

Limit switches are also useful for automatic Zero position calibration.

4.3.3.5. Limit switches connecting instructions¶

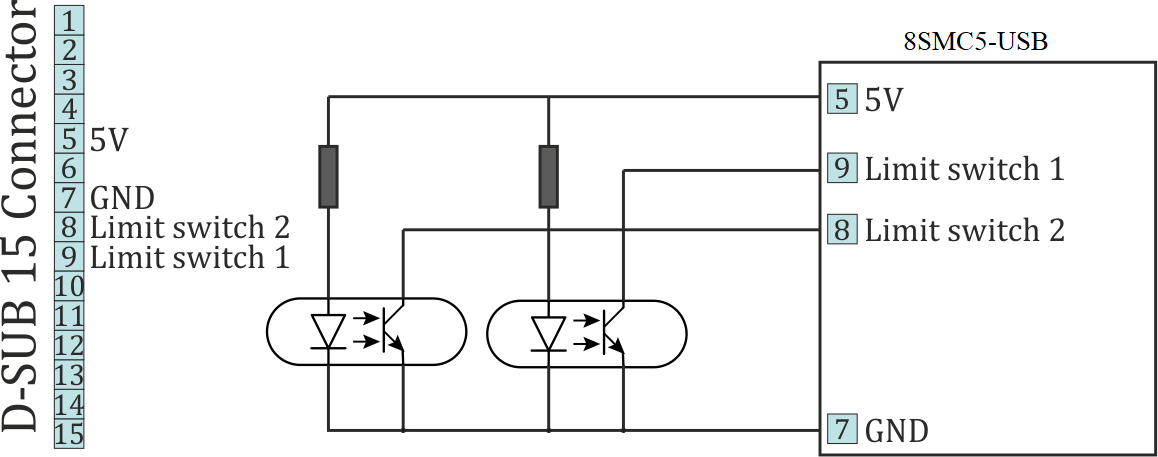

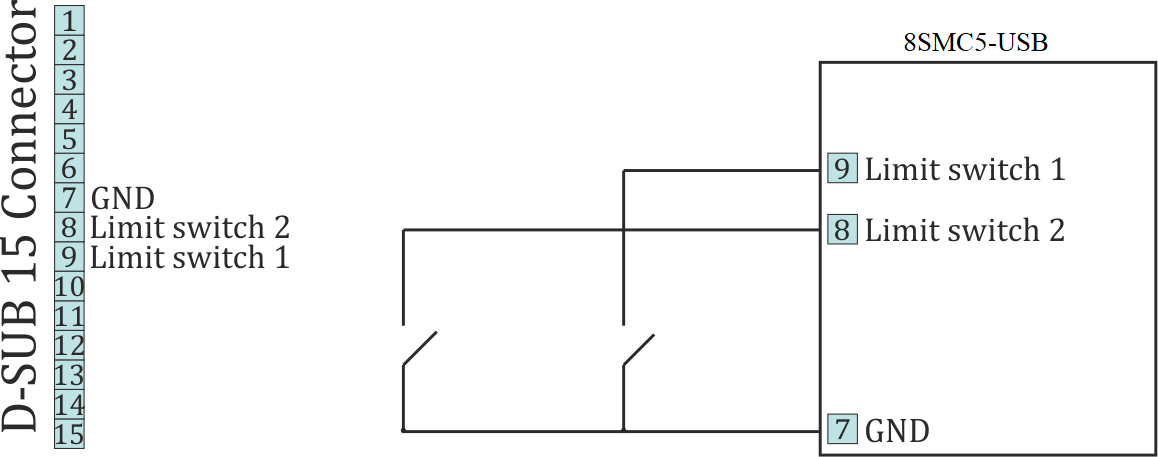

Limit switches should be connected to D-SUB connector pins as it is shown at the diagrams:

4.3.3.6. Limit switches location on translators¶

The settings of which limit is left or right is required by the controller. Sometimes it is unknown a priori, just it is clear that both limit switches are connected and fire if the corresponding limit of the motion range is reached. The stage jam is possible if the limit switches are configured improperly. Therefore, the controller supports just a simple detection of incorrectly configured limit switches, shutting down the movement on both of them. Please make sure that their polarity is configured correctly and the shutdown mode is activated on both of limit switches. The flag of improper limit switch connection detection should be turned on in corresponding XiLab software menu. Start the movement to any direction until the limit switch shuts the movement down. If there was right-side movement but the left limit switch became active, or vice versa, the limit switches should be interchanged (see the Motion range and limit switches chapter). If the improper actuation of the limit switch is detected and if the corresponding feature is set in the Critical parameters menu, the controller can turn the Alarm mode on.

Warning

The protection against mistaken limit switches connection doesn’t guarantee the complete solution of the problem, it only makes the initial configuration procedure easier. Particularly, don’t start the movement if any of the limit switches is active, even if the protection is on.